Introduction

Before we get started in designing our glasses, let's look at the tools involved. We will be utilizing a digital caliper for measurement, CAD for precise drawing and the laser cutter to quickly make a phsyical object.

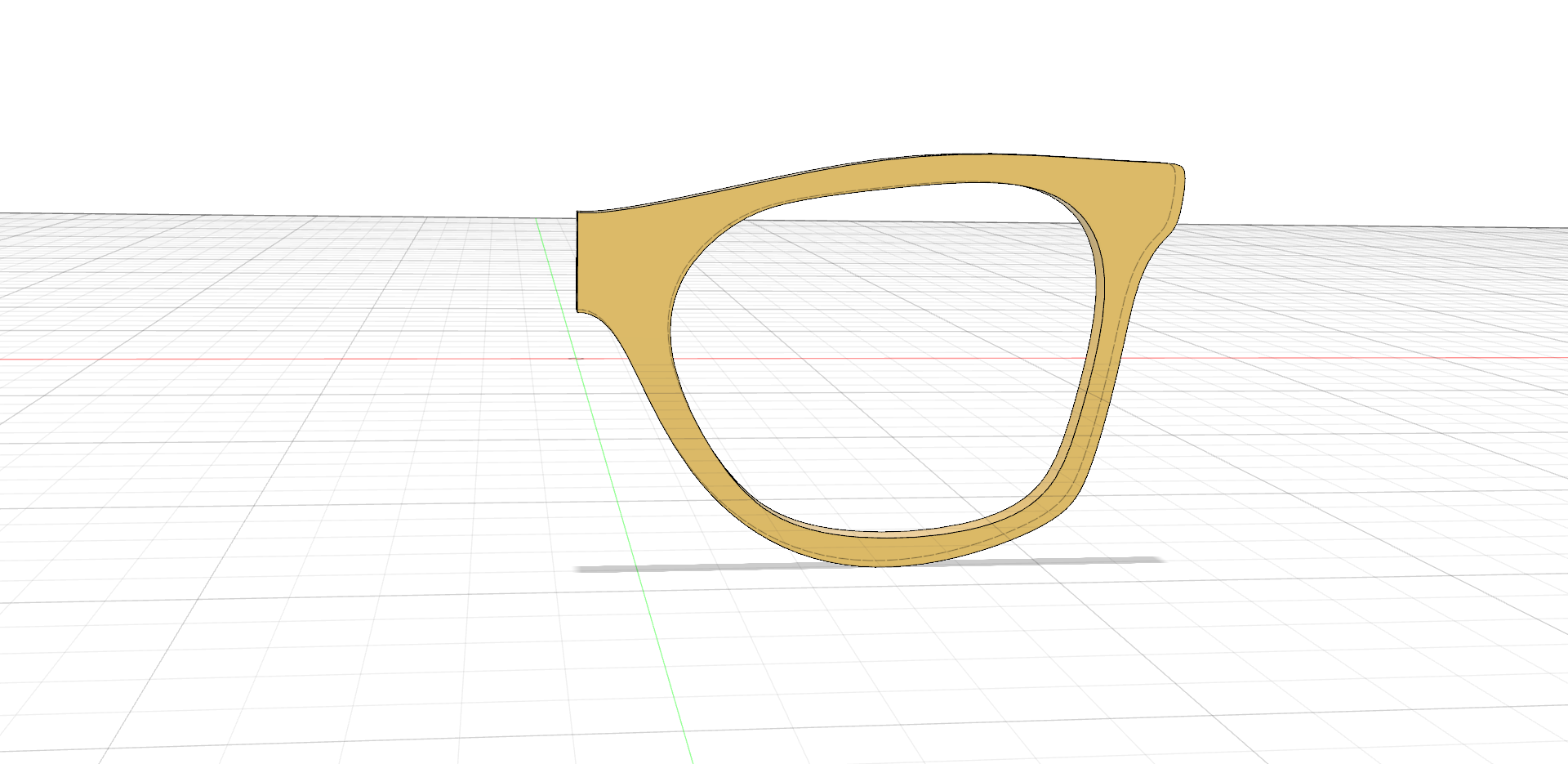

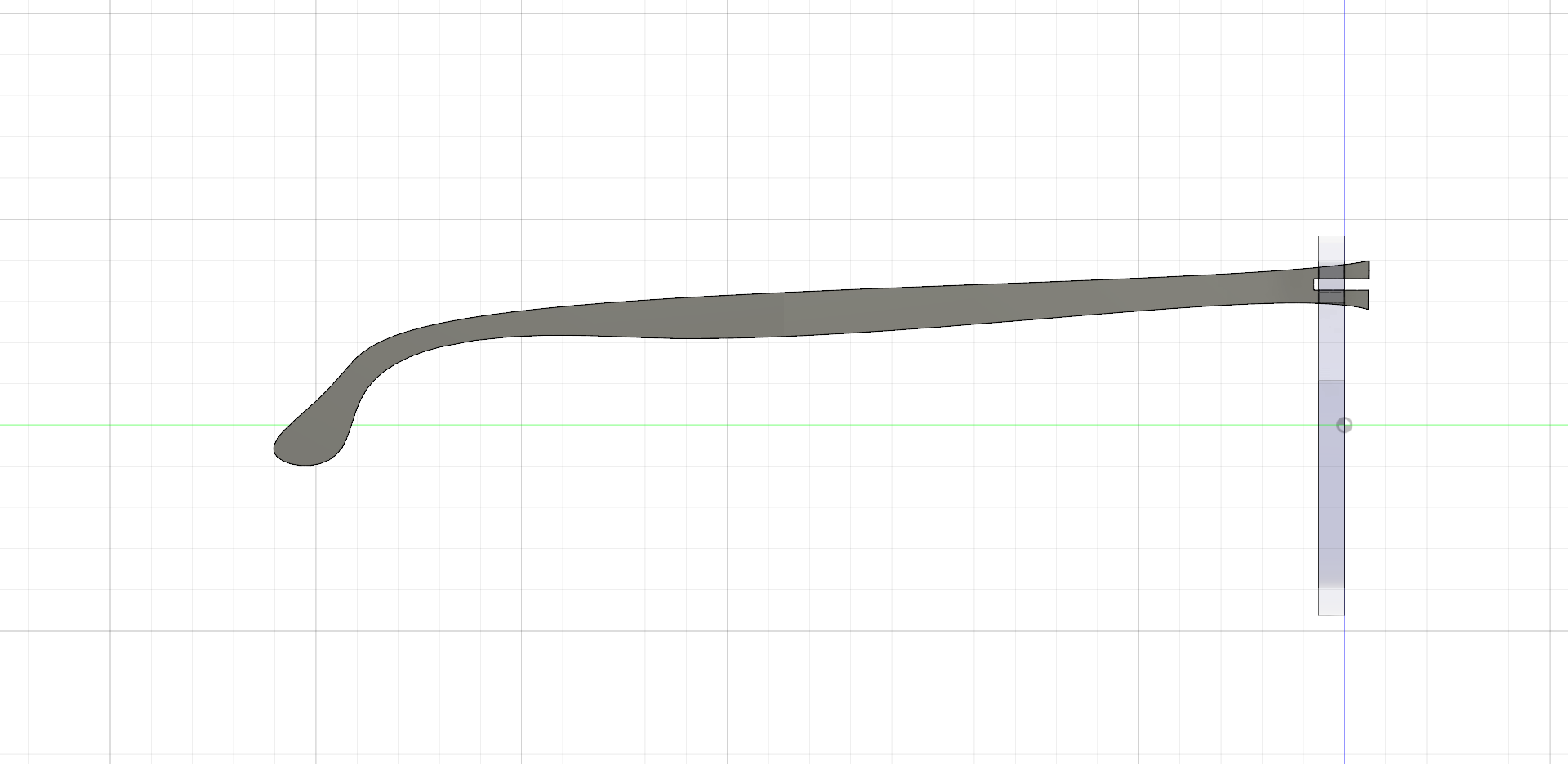

Beginning Design

We are going to be using a program called Autodesk Fusion 360, which is free for students and supplied on these laptops. You will need to create an account using the link below. From here we will import and trace the photo of our lens.

Calipers & CAD

A digital caliper is an indispensible tool for getting precise and accurate measurements on physical objects. We will use them to measure our lenses and check the for the overall sizing of our sunglasses. Glasses lenses are measure from the furthest points horizontally and vertically. Determine your lens size by measure the lens and take a picture of your lens on a white background without shadows.

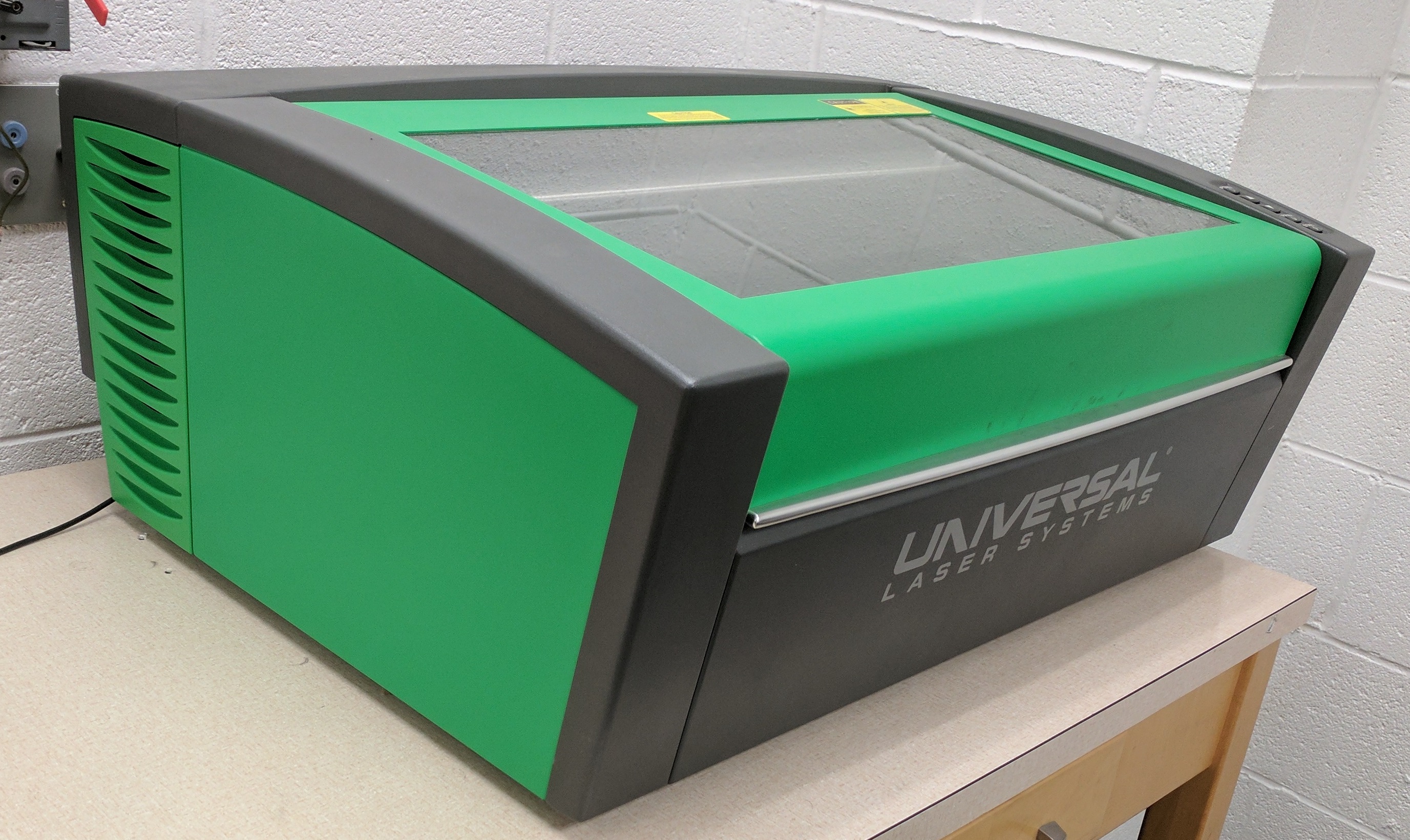

Laser Cutter

We will be prototyping with some 3mm thick birch plywood and the Universal VLS 3.50 Laser Cutter. We will have a short demo of the laser cutter and how it works and its safety precautions.